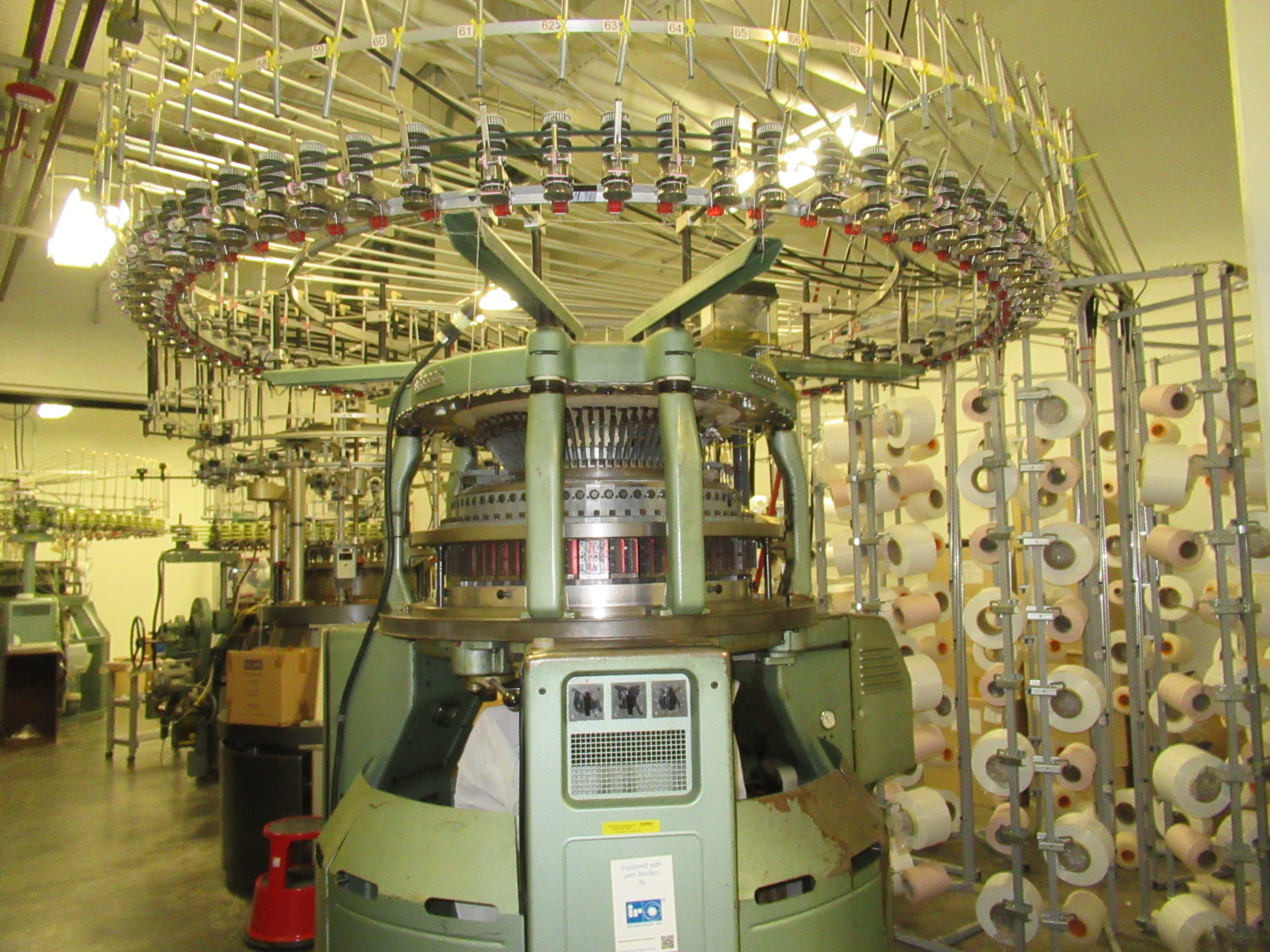

KNITTING

We knit using highly automated machines, which can create multifaceted knitted fabrics and Garments as per our customer’s needs. Our knitting process is capable of handling multi-color yarns with the task of getting the fabric with perfection.

JERSEY – INTERLOCKS – FLEECE – POINTEL RIB

Machineries : Mayer & Cie, Pailung, Smart

Production : 5 tons / per day

Utilisation : 3.5 tons / per day

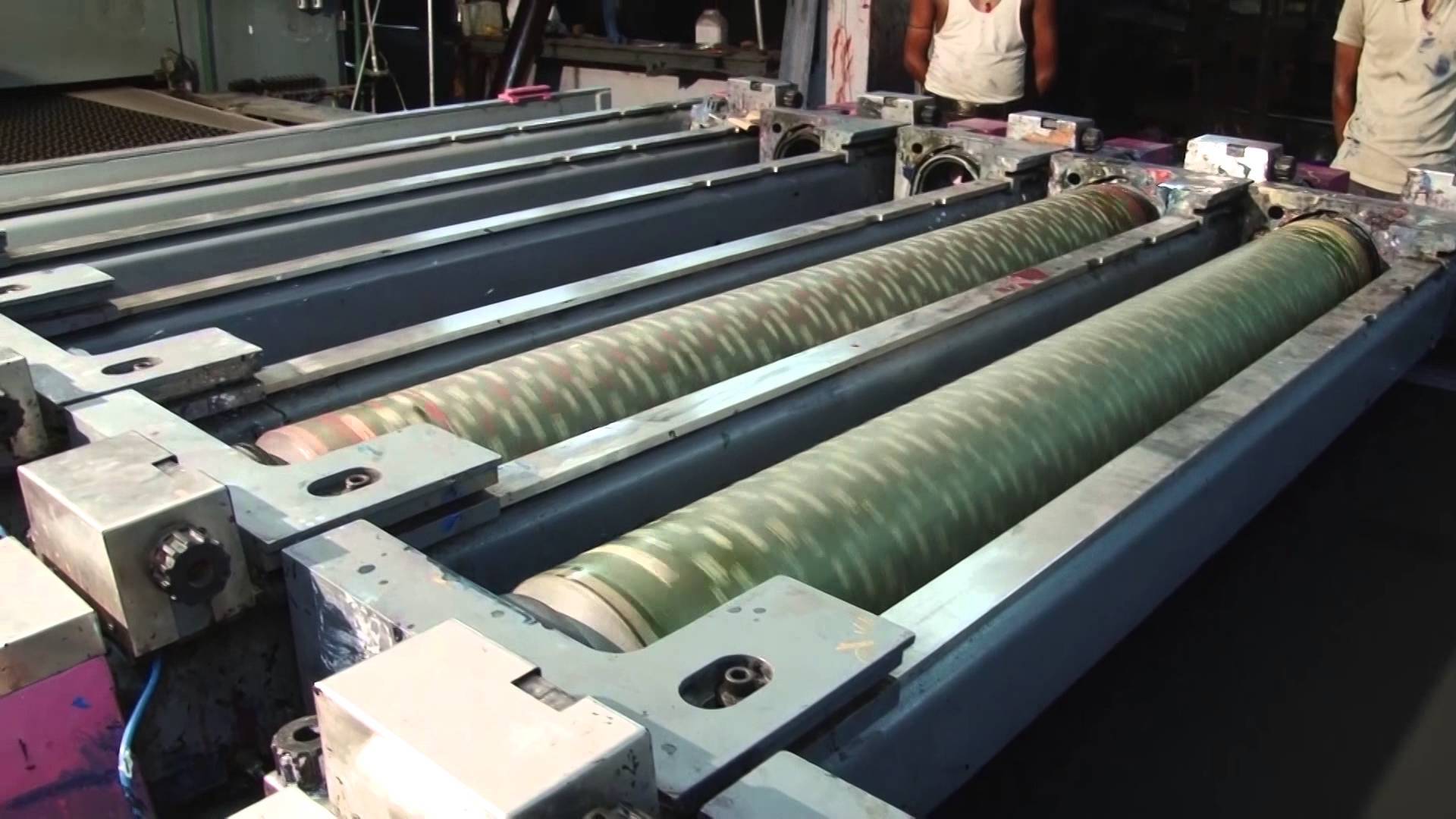

PRINTING

We use printing materials of high quality, which are not harmful to health, and the materials are environment-friendly. It preserves their characters for a longer period even after several washes. We dispose of the printing wastages in a professional manner to preserve nature for future generations. We print our quality on your garments with:-

High Density

Discharge

Flock and Glitter

Foil

Cracking Gadi

Foam Print

Thermochromic Print

Machineries : M & R USA - 2M/cs - Alpha and Challenger

Production : 0.4 Million Pcs Per Month

Utilisation : 0.25 Million Pcs Per Month

WASHING

Our washing resource has a capacity of 235 kgs which can give an output of 60 tons in a month. We have listed down the types of wash that we provide in our factory:-

Softner Wash

Silicon Wash

Hot Wash

Hot + Softner Wash

Hot Soaping

Bio Wash

Bio Wash + Softener

Spray Tumble

Crushing

Enzyme Wash

Vintage Wash

Gsm Increase

Stone Wash

Oba Wash

Denim Wash

Stiffener Wash

Sewability Softner

Acitic Hot Wash

Machineries : Stalwart - 3 machines 10kg, 50kg, 100kg

Utilisation : 1600 kg per day

Production : 2000 kg per day

GARMENTING

1) CUTTING

Our new cutting machine clubbed with CAD ensures the cutting process is done at 100% perfection to fulfill the customer’s expectations. Reduces the wastage of fabrics. Our cutting machine is one of the leading brand machines in the world which reduces the garment process time substantially.

Cut With CAS Design

– For Optimum Utilisation Of Fabrics

– To Ease The Stitching and Finishing

– To Reduce The Wastage Process

Machineries : Morgan Tecnica

Production : 0.4 Million Pcs Per Month

Utilisation : 0.3 Million Pcs Per Month

2) PRODUCTION

We use imported stitching machines of Juki, Yamato, etc., to get perfection in our garments. Our continuous supervision by the quality control department at each level of stitching enables us to optimize our production.

We stitch to exalt you with :-

T-shirt – Casual Wear – Work wear – Other Garment

Machineries : 800 Machines

Production : 0.35 Million Pcs Per Month

Utilisation : 0.27 Million Pcs Per Month

3) FINISHING

At NSP Tex, we believe that attention to detail is what sets our t-shirts apart. Our Finishing Section is where we put the final touches on each garment, ensuring that every t-shirt leaving our facility is of the highest quality. With state-of-the-art machinery and a skilled team of experts, we take pride in delivering t-shirts that exceed your expectations.

If you love something, wear it all the time… Find things that suit you. That’s how you look extraordinary.

– Vivienne Westwood